Phone:0411-87918678

Tel:13998428656

E-mail:fluidscare@163.com

Add:No.27 Shizi Street Dalian Industrial Park China

Product introduction

JY series automatic reagent device is a device for automatic medication and continuous manufacturing of polymer solution. It is mainly used in sediment, coagulation, floating and sludge dewatering and is sued for automatic mixture and inject of coagulant or flocculant. Its raw materials cover power medicament such as polyacrylamide (PAM), starch, urea and so on.

JY series automatic reagent device is a device for automatic medication and continuous manufacturing of polymer solution. It is mainly used in sediment, coagulation, floating and sludge dewatering and is sued for automatic mixture and inject of coagulant or flocculant. Its raw materials cover power medicament such as polyacrylamide (PAM), starch, urea and so on.

Flow and dry powder addition machine with adjustable powder amount produced by our company is dissolution machine with automatic ratio of powder. It can be used to distribute solution with varying density. Powder machine with spiral pole delivery means is distributed in material discharge and handy in adjustment. Adjustment of frequency of transducer helps adjust power amount per hour. This device has such advantages as low error of density and convenient adjustment. The device has manual and automatic work modes.

The process of making dry powder solution is accomplished via various solution tanks by stages with separation among solution tank to ensure best response time and constant density in each solution tank, to avert any direct linkage between prefabrication tank and storing tank of medical soup or linkage of automatic control system and liquid level controller in the storage tank. Once the liquid level reaches the low order, it will trigger open the inflow solenoid valve. The dry powder addition machine will be switched open. The dosage is set up following water amount to acquire accurate density. When the liquid level reaches the maximum level, the recycle process ceases. Stirring procedure during set-up of stirrers helps avoid prediction of drugs in the storage tank. Once the liquid level reaches the low level, it will trigger the electronic valve to switch open. The dry power addition machine will be switched open. The dosage is set up following water mount to acquire precise density. When liquid level reaches the highest point, the recycle process stops. Stirring procedure during set-up of stirrer helps avoid sedimentation of mendicant in the medication tank.

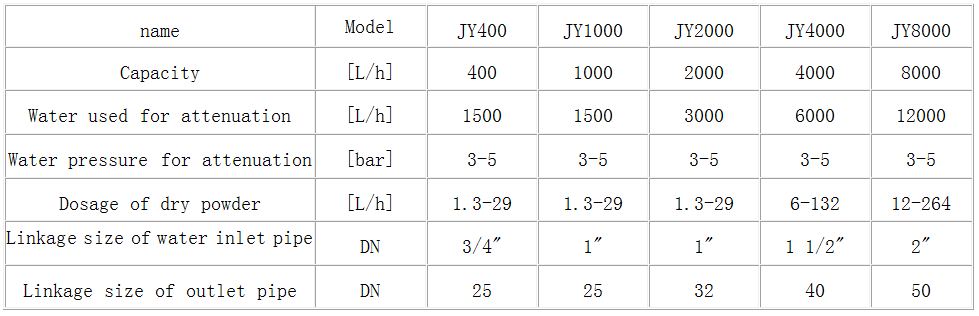

Product specification

Parameters of automatic medication device

Structure

1. Spiral feeding device

2. Inlet device

3.Soaking dissolving device

4. Mixed drug storage tank

5. Liquid drug transmission system

6. Electronic control system

Characteristics of equipment

1. Highly-concentrated integration device.

2. High automation degree.

3. Small in size, convenient in operation, handy in installation. Only linkage of water resources and power resources is needed for on-spot installation.

4. Secured and reliable for work. The system will automatically turn off with alerting signal in case of failure.

5. Stable in performance, automatic control model. Dosage of dry powder can be adjusted following changes of water amount.

6. Sound in anti-corrosiveness. It adopts engineering plastics and stainless steel materials when it is in contract with the medium.

7. It can be applicable to powder substances, particles, fiber and other materials and can be applied to release and mixture of liquid materials.

8. Pharmaceutical dosage is precise and adjustable to ensure disposal effects and avoid waste.

9. Powerful technological backup. It can be designed following users’ requirements.

Scope of application

1. Coagulation aide for city sewage

2. Coagulation aid for industrial waste water

3. Disposal of water

4. Sludge treatment and sedimentation

5. Paper-making and smelting

6. Petrochemical industry