Phone:0411-87918678

Tel:13998428656

E-mail:fluidscare@163.com

Add:No.27 Shizi Street Dalian Industrial Park China

Product introduction

Nut shell filter is designed to remove tiny solid and liquid hydrocarbon from the water, as a secondary or tertiary water treatment.

Introduce the oily water containers and allocation, in order to ensure the uniform flow of the whole container.When water flows through a container, shell medium and small solid adsorption oil, allowed to leave clean water container.

Nut shell filter is usually used to achieve export oil concentration is less than 5 PPMV, even can be lower than 1 PPMV concentrations.

Nut shell filter can remove particles of solid size to 3 microns.

During operation, oily water flowed into the container and the nut medium. Medium and small solid adsorption oil and prevent them by container.With the passage of time, the oil accumulation in the medium and small solid.For the regeneration of filter medium, the adsorption of oil by backwashing and small solid wash away from the medium.

Our company produces the fruit shell filter based on fruit shell filter material of the suspended solids in waste water adsorption filtration water treatment equipment.Cover an area of an area small, without adding chemical cleaning, saves the backwashing water volume, high degree of automation, etc.

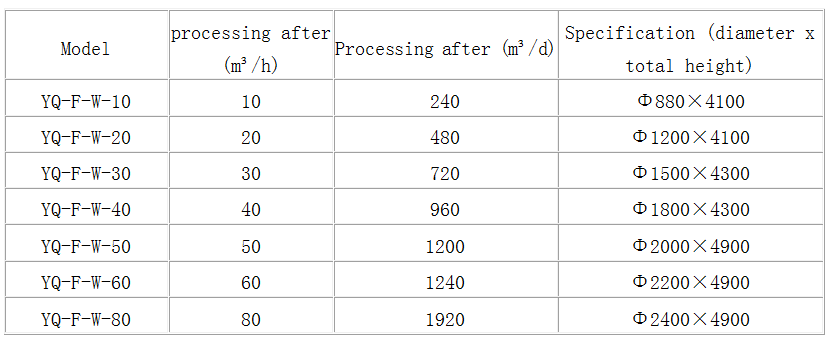

Product specification

structure

Nut shell filter usually includes several parts:

1. The nut medium

2. The fruit shell filter vessel

3.Reverse washing device

4. into the water pump

5. Lifting pump

6. The exhaust pipe

Characteristics of the equipment

1. The backwashing water to be filtered water, the water pump work for normally open state, to avoid the water pump frequent starting;

2. No need backwashing water tank, backwashing pump;

3. No gas, reduce corrosion and the resulting environmental problems;

4. Without the traditional nut shell filter backwashing chemicals used;

5. Backwashing time less than 20 minutes, backwashing water amount for 50% of the traditional filter unit;

6. Backwashing softness and thoroughly, reduce the loss of filter material to avoid the traditional mixing when cleaning filter material breakage phenomenon;3 months before the initial use of filter material is 5% ~ 10% of transshipment, a year after filter material of recharge is 5% ~ 5%;

7. After backwashing of filter material by power lay flat, prevent filter bed layer, ensure uniform filter layer;If the filter material is formed by gravity filter bed, so small filter material stays at the top of the filter bed, and a larger filter material stay in the bottom of the filter bed, filter will focus on the process of the filter bed inside at the top of the 200 mm to 300 mm.And after backwashing filter material by power lay flat, can accommodate more sludge, increase the filtration time, reduce the flow velocity, clean or backwash, so as to reduce the processing cost;

8. Unique designs, make the water catchment and drainage device is not easy to jam, reducing the overall maintenance cost;

9. At least the outside network and start the program, easy operating platform and operation training, environmental protection equipment to provide simple and reliable.

Scope of application

1.Oily wastewater treatment: The oilfield to oil and suspended solid.

2. Industry oil-bearing water treatment: go to oil and suspended solid.

3. The civil water and industrial water treatment, removal of suspended solids in water, improve water quality.

4. Suitable for municipal, chemical, petrochemical and metal processing and power generation.